Advanced Metal Manufacturing for Global OEM Projects

With 26 years of experience in integrated metal manufacturing, Meituo has built a complete metal manufacturing system. We are good at mold, die casting, processing, stamping, cast iron, metalworking, etc. We also have advanced data management and a complete quality inspection process to ensure stable quality and consistent performance in every aspect of your OEM project from product development to mass production.

OUR CAPABILITIES

Integrated Manufacturing Capabilities Overview

Through one-stop customized metal production capabilities, we reduce supply chain steps, shorten production cycles, and ensure that dimensions, performance, and consistency are stably controlled within the same system. We are committed to providing your OEM projects with higher reliability, faster delivery speed, and a more transparent cost structure to help you remain stable and competitive in the long term.

Mold Design & Engineering

Our mold team analyzes mold and product structures, including release angles, shrinkage and gating, venting and cooling design. With UG and JSCAST software and nearly 30 CNC and EDM machines, we can independently develop and build molds.

Die casting

We have large die-casting capacity with annual output near 10,000 tons. We operate 20 aluminum die-casting machines from 160T to 1650T, supported by slag removal units, a central melting furnace, and gas/electric insulation furnaces to keep stable product quality.

Precision Machining

Equipped with advanced processing equipment both domestically and internationally, our company provides high-quality processing services, including turning, milling, drilling, tapping, and more. We specialize in processing large, precision, and complex die-cast products.

Stamping

The stamping workshop has dozens of presses, including 125t, 160t, 200t models and 100t, 200t, 315t, 500t hydraulic presses. It also includes multiple shearing machines and supports independent design and manufacturing of progressive dies.

Csat Iron

We specialize in small and large batches of multi-variety parts, including ductile iron QT400-700 and gray iron HT150-350, providing global partners with products for different applications. These are mainly used in washing machines, air compressors, and pumps.

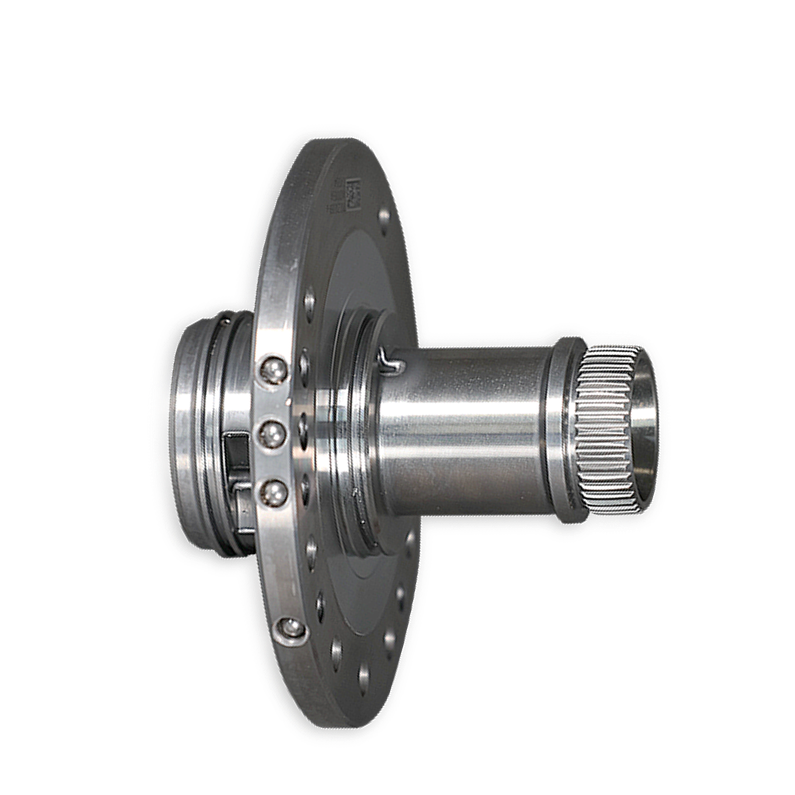

Metalworking & Shaft

Strictly adhere to 5S standards, with the workshop prioritizing the long-term economic and stable operation of equipment to produce high-quality products. The concentricity of shaft products can reach 0.003mm.

FACTORY OVERVIEW

Modern Metal Manufacturing Facility

Meituo has an integrated metal manufacturing base of more than 33,000 m² and is equipped with 640+ units of equipment. The factory includes a Mold Design & Engineering Center, Die Casting Workshop, Stamping Workshop, Precision Machining Workshop, Metalworking & Shaft Workshop, Cast Iron Workshop, and a Quality Inspection & Testing Center. We can process small precision parts and large structural parts at the same time. Through standardized management and full-process testing, we continue to output stable batch quality and meet long-term supply needs. We support different cooperation models from small batch trial production to large batch long-term supply. We can flexibly arrange production lines according to structural difficulty, quantity scale, and delivery pace to provide stable and reliable manufacturing support for your project. We provide you with metal manufacturing solutions that truly fit your needs.

advanced manufacturing equipment

Our production equipment totals 640+, equipped with advanced die-casting machines, automated machining centers and professional testing equipment. Our equipment can support a variety of metal manufacturing processes, achieving high repeatability, stable accuracy and scalable production capability.

Engineering and Technical Team

We have more than 280 professionals, including more than 50 engineers and technical experts with master's or bachelor's degrees. They work closely with overseas consultants from Japan and Taiwan and domestic universities to promote continuous technological innovation and process optimization.

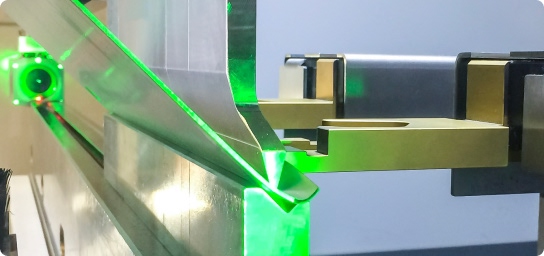

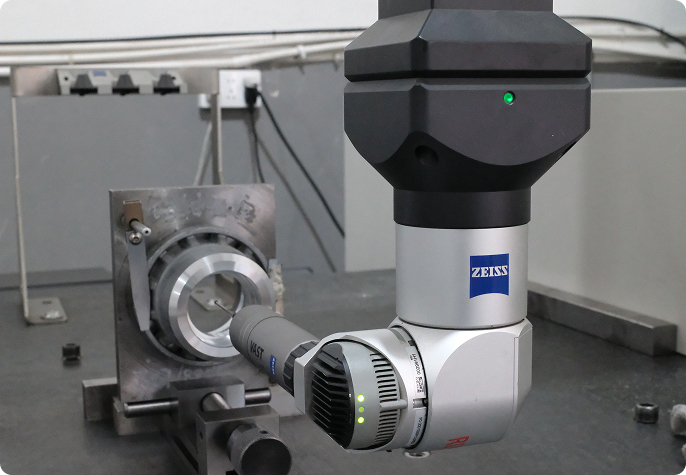

Quality control and testing

Each production process is strictly managed under the IATF16949 and ISO9001 systems. Metto is equipped with advanced testing equipment, including hardness testers, spectral analyzers, salt spray test chambers, tensile testing machines, Zeiss coordinate measuring systems and X-ray testing equipment to ensure product quality, stability and compliance.

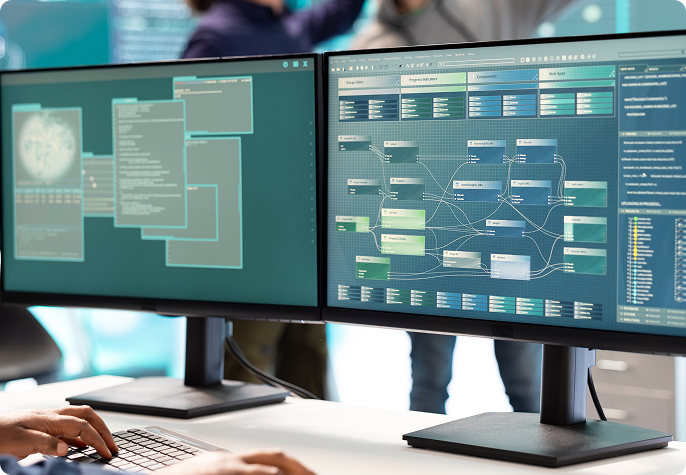

digital manufacturing system

Through the integrated application of MES, PDM and QMS digital management platforms, Metto realizes real-time monitoring of the production process, production traceability and data-driven quality management. These systems improve the transparency of the manufacturing process and overall operational efficiency.

Manufacturing Process Flow

From Design to Delivery

Quality Systems You Can Trust

CERTIFIED MANUFACTURING ASSURANCE

Every part we produce is backed by internationally recognized certifications and continuous quality monitoring.

Meituo operates under globally recognized quality systems including IATF16949, ISO9001, ISO14001, ISO45001, ISO14064, and ISO50001. These certifications ensure compliance with international manufacturing and environmental standards across all processes.

By integrating certified quality systems with digital control platforms, Meituo achieves consistent performance, full traceability, and reliable delivery — establishing itself as a trusted metal manufacturing partner for leading global brands.

SUSTAINABILITY & RESPONSIBILITY

Sustainable Metal Manufacturing

Meituo continues to pay attention to environmental management and employee safety in metal manufacturing. Through ISO 14001 Environmental Management System Certification and ISO 45001 Occupational Health and Safety Management System Certification, we systematically manage environmental impact and occupational health and safety during the production process.

Contact Our Metal Manufacturing Team

Discuss your OEM project with our metal manufacturing experts — we provide custom die casting, machining, and fabrication solutions tailored to your design.