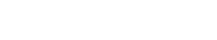

Mold Design & Engineering Center

Our company has experienced mold designers who can conduct comprehensive analyses of mold and product structures, including mold release angles, product surface shrinkage, casting system design, venting system design, cooling system design, etc.

At the same time, the company is equipped with UG 3D modeling software and JSCAST casting simulation software, and has the ability to independently develop molds.

We have nearly 30 imported high-end CNC machining centers, spark machines, and other equipment.

die casting workshop

Meito possesses large-scale die-casting product manufacturing capabilities, with an annual production capacity of nearly 10,000 tons of die-cast components. The company has successively introduced advanced die-casting machines from both domestic and international sources. Currently, it operates 20 aluminum alloy die-casting machines ranging from 160T to 1650T, along with a comprehensive range of auxiliary equipment, including the top-tier domestic slag removal machine, as well as state-of-the-art facilities such as the Sijiexi central melting furnace, natural gas insulation furnace, and electric insulation furnace. These resources collectively provide robust equipment support to ensure the highest quality of products.

stamping workshop

The sheet metal workshop is equipped with dozens of presses, including 125t, 160t, and 200t models, as well as hydraulic presses of 100t, 200t, 315t, and 500t capacities. It also has several small and large shearing machines and possesses the capability to design and manufacture progressive dies.

Precision Machining Workshop

Equipped with advanced processing equipment both domestically and internationally, our company provides high-quality processing services, including turning, milling, drilling, tapping, and more. We specialize in processing large, precision, and complex die-cast products.

metalworking workshop & shaft workshop

Strictly adhere to 5S standards, with the workshop prioritizing the long-term economic and stable operation of equipment to produce high-quality products. The concentricity of shaft products can reach 0.003mm.

cast iron workshop

We specialize in small and large batches of multi-variety parts, including ductile iron grade QT400-700 and gray iron grade HT150-350, providing our global partners with products for different applications. These are mainly used in areas such as washing machines, air compressors, and pumps.

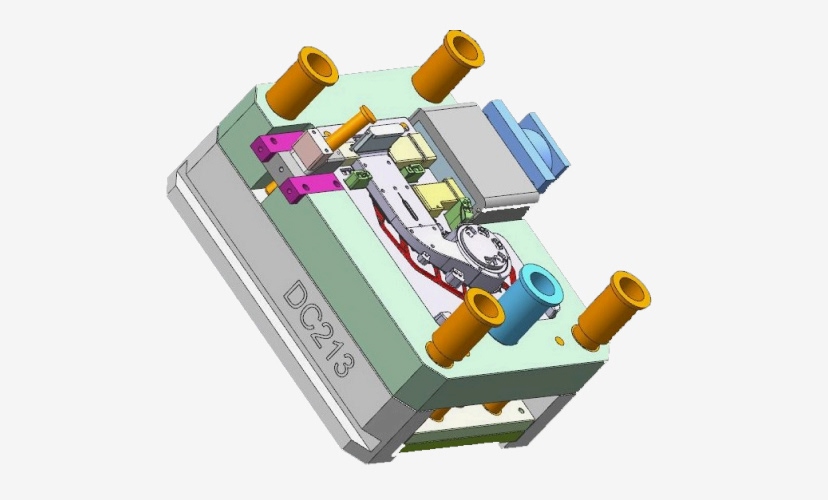

Quality Inspection & Testing Center

Our Quality Inspection & Testing Center is equipped with a full range of advanced testing instruments, enabling precise and consistent evaluation of various metal components—including material composition verification, dimensional measurement, mechanical property testing, and corrosion-resistance analysis.

We strictly follow standardized procedures across all key processes, including hardness testing, spectrographic analysis, CMM inspection, tensile testing, salt-spray testing, and X-ray flaw detection.

Maintaining stable, high quality in mass production is a core requirement of our quality management system and the foundation for delivering high-standard products to our OEM customers.